Over recent weeks, I have wasted invested a lot of time investigating the Gaggia boiler thermodynamics. (All part of my master plan to have the entire machine at a stable temperature inside 2 minutes from power on.) A major obstacle to getting a stable temperature quickly is that the brew head takes for ever to warm up. Whilst thinking about this, I hit on an idea for improving the heat transfer from the aluminium boiler shell to the brew head: put heat-sink compound in the join between the shell and the brew head.

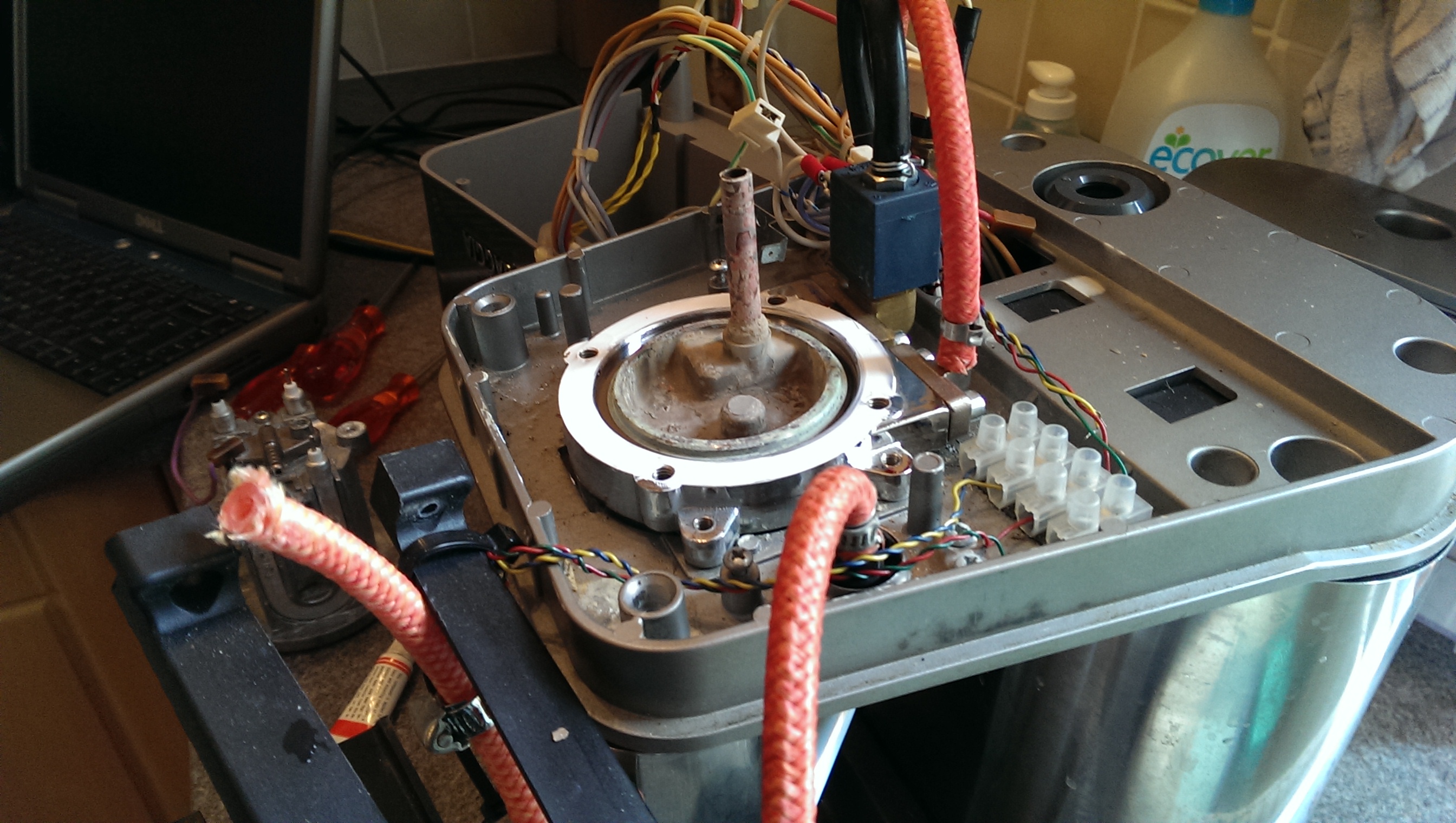

Here it is, the white grease around the outside of the gasket groove:

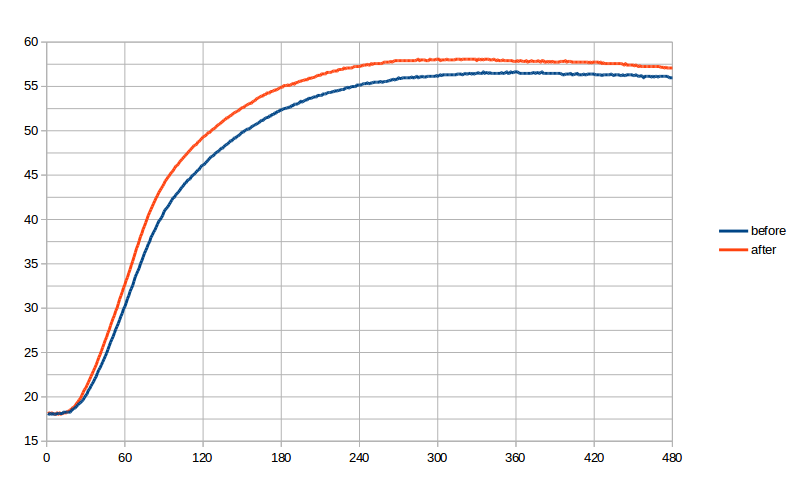

Does it make a difference? Why, I’m, glad you asked. As it happens, I had the presence of mind to measure and plot before and after curves. Pictured below is the temperature response (in °C) to 60s of full power, followed by 420s of zero power.

A clear improvement – nearly 10% faster heating1Which, for those of us who love to optimise systems, is a result!. But worth dismantling the machine? I leave that to the reader to decide. But I should mention one big caveat: make sure you have a replacement boiler gasket if the machine is old. The likelihood of an old gasket surviving the disassembly and reassembly is low.

Oh, and the results of my investigations into the thermodynamics? All nicely documented here.

| ↑1 | Which, for those of us who love to optimise systems, is a result! |

|---|